Products > Casing Scraper

| Size | Body OD | Kits One set | Stab Kits |

| 4-1/2 | 92 | One set with availability of blades to scrap | Spiral or straightening centralizer. |

| 5 | 94 | ||

| 5-1/2 | 110 | ||

| 6-5/8 | 136 | ||

| 7 | 136 | ||

| 9-5/8 | 203 | ||

| 10-3/4 | 228 | ||

| 13-3/8 | 286 | ||

| 20 | 286 | ||

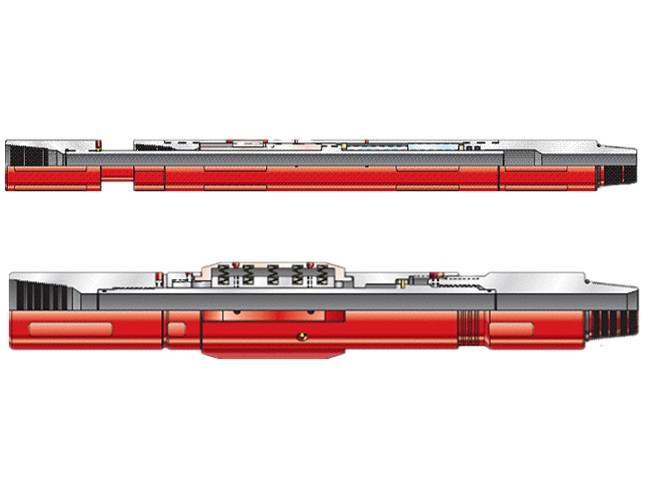

KWCS Model Non- rotating casing scraper

1. Overview

KWCS casing scraper is an internal tool used for removing the obstructions or foreign material from inside the walls of casing, such as residual cement, clay lump, and the burr, scales coming from casing rolling, the perforating charge which is set on the wall during sand preventing perforating inside, as well as rust, scale, hard paraffin on the production casings.

2. Structure of Scraper Part

KWCS Scraper is made up of mandrel, centering sleeve, upper support seat, hoop scraper, semi-annular plate, lower support seat, fixing sleeve, lower scraper, wearing ring, adjusting ring, spline body, gland nut, lower joint as well as other components. The hoop scraper and lower scraper can be stretched out and drew back to removing the dirt layer-by-layer according to the thickness of obstructions on the inner wall of casing; Meantime, the scraper and mandrel can mutually rotate. Mandrel and spline body are connected by spline pair connection, it can achieve the torque transmission, transfer the upper torque to the lower tools.

3.Technical Data:

| Model |

Max. OD (inch) |

Max. OD. of Blade (inch) |

Casing Weight |

ID (inch) |

Overall Length (inch) |

Connection(API) UP X DOWN |

Suitable casing (inch) |

| KWCS103 | 4 1/16 | 4 5/8 | 15-18# | 1 3/16 | 60 | 2 7/8REG×2 7/8REG | 5 |

| KWCS148 | 5 13/16 | 6 5/8 | 23-32# | 1 9/16 | 82 | NC38×NC38 | 7 |

| KWCS210 | 8 1/4 | 9 1/16 | 40-47# | 2 13/16 | 93 | NC50×NC50 | 9 5/8 |

| KWCS346 | 11 1/4 | 127/8 | 71.43#-107.15# | 2 13/16 | 100 | 65/8REG×65/8REG | 13 5/8 |

COMBO Type Casing Scraper

COMBO type casing scraper and GGQM/QC are used in conjunction, the annular scraper and the lower scraper can be internal and external expansion automatically according to the thickness of the casing wall dirt, to scrape dirt layer-by-layer. At the same time between scraper and spindle to turn to each other. The mandrel and the outer tube by using spline connection, can realize the torque transmission.

|

type |

Maximum outside diameter of body mm(in) |

Max diameter of scraper mm(in) |

Hydrophthalmia mm(in) |

Total Length mm(in) |

connection thread |

| COMBO5 | 105(4.13) | 127(5) | 25(1) | 2000(78.7) | NC31 |

| COMBO6.5 | 138(5.43) | 158(6.22) | 40(1.61) | 2798(110) | NC38 |

| COMBO7 | 148(5.82) | 170(6.69) | 40(1.61) | 2798(110) | NC38 |

| COMBO9.5 | 210(8.26) | 229(9) | 70(2.76) | 2821(111) | NC50 |

KWXZ Model Casing Scraper

KWXZ casing scraper is one of auxiliary tools in well completion, testing and downhole working, It is mainly used for cleaning cement, sand, residual bullets, rag, and otherobjects on casing inner surface, in order to keep casing inner surface cleaning and the drilling tools working normally. KW XZ casing scraper can't be used in drilling operation.

It is one kind of new type casing scraper, not only as general fixed casing scraper, but also used as a rotating type structure casing scraper. If as a fixed casing scraper, as long as increase adjustable pad locates in upper sub to make it non-rotate, otherwise decrease adjustable pad. It will be used as a rotating casing scraper.

Technical Data:

| Sharp-Razor™ Series Non Rotating Casing Scraper DIMENSIONAL DATA | ||||||

| Nominal OD(in) | Weight (ppf) | Connection | Centralizer OD(mm) |

Scraper Cage OD (mm) |

ID(in) | Length (in) |

| 4-1/2” | 11.6-15.1 PPF | 2-3/8 REG B*P | 96 3.78’’) | 4.05’’ | 20 | 65 |

| 5” | 11-24.1 PPF | 2-3/8 REG B*P | 9.94’’ | 4.56’’ | 20 | 65 |

| 5-1/2” | 14-43.1 PPF | 2-3/8 REG B*P | 4.33’’ | 5.03’’ | 1 | 69 |

| 6-5/8” | 20-32ppf | 3-1/2 REG B*P | 5.31’’ | 5.86 | 1 | 70 |

| 7” | 26-35 lb/ft | 3-1/2 REG B*P | 5.83’’ | 6.3’’ | 1.18’’ | 74 |

| 9-5/8” | 43-53.5 lb/ft | NC50 B*P | 8.07’’ | 8.77’’ | 2.81’’ | 86 |

| 10-3/4” | 32.75--85.3 | 6-5/8 REG B*P | 9.17’’ | 9.76’’ | 2.81’’ | 98 |

| 13-3/8” | 48-54.5-61-68-72 | 6-5/8 REG B*P | 12.32’’ | 12.83’’ | 2.81’’ | 110 |

Cleaning Casing Scraper

The Casing scraper is used to clean the cement, mud, embedded bullets, rust, mill scale, paraffin, perforation burrs and other substances from the inside walls of casing. Maintaining a clean casing ID is important to the operation of all tools used in drilling the well. Adhesive materials on casing walls will frequently cause these tools to become difficult to operation.

| Sharp-Razor™ Series Non Rotating Casing Scraper DIMENSIONAL DATA | ||||||

| Nominal OD(in) | Weight (ppf) | Connection | Centralizer OD(mm) |

Scraper Cage OD (mm) |

ID(in) | Length (in) |

| 4-1/2” | 11.6-15.1 PPF | 2-3/8 REG B*P | 96 3.78’’) | 4.05’’ | 20 | 65 |

| 5” | 11-24.1 PPF | 2-3/8 REG B*P | 9.94’’ | 4.56’’ | 20 | 65 |

| 5-1/2” | 14-43.1 PPF | 2-3/8 REG B*P | 4.33’’ | 5.03’’ | 1 | 69 |

| 6-5/8” | 20-32ppf | 3-1/2 REG B*P | 5.31’’ | 5.86 | 1 | 70 |

| 7” | 26-35 lb/ft | 3-1/2 REG B*P | 5.83’’ | 6.3’’ | 1.18’’ | 74 |

| 9-5/8” | 43-53.5 lb/ft | NC50 B*P | 8.07’’ | 8.77’’ | 2.81’’ | 86 |

| 10-3/4” | 32.75--85.3 | 6-5/8 REG B*P | 9.17’’ | 9.76’’ | 2.81’’ | 98 |

| 13-3/8” | 48-54.5-61-68-72 | 6-5/8 REG B*P | 12.32’’ | 12.83’’ | 2.81’’ | 110 |

Technical Data:

HC Hydraulic Scraper

The new HC is composed of centralizers, device and sleeve combination switch in series, with a drill pipe connection at both ends of the thread. It workshop in conjunction with the drilling, grinding, milling, through wells and other working tools, so that a downhole tool to complete a variety of different jobs, reduce the number of the drill string from the next, greatly improve operational efficiency and reduce mining casts. After drilling, milling, grinding, through wells job is completed by pitching from wellhead pressure, the scraper blade play. Hydraulic scraper device can work the same as a conventional scraper device. And loop holes connected to scrape beneath the sleeve wall switch is also open at this time can carried out reverse circulation flushing.

HC – Hydraulic scraper

The new hydraulic scraper has the following characteristics: in drilling, milling, grinding and other operations, scraper device of the blade is limited in the body’s groove, in the role of the upper centralizer, stretched out less scraper not to scratch on the inner wall of the casing, thus will not affect to normal operation of other tools.

| specification | Gauge outside diameter (mm) |

Gauge in casing flow area (mm2) |

drift diameter (mm) | Gauge length (mm) | Total Length (mm) |

| 5" | Φ102 | 990 | Φ25 | 500 | 650 |

| 5 1/2" | Φ115 | 1110 | Φ30 | 500 | 650 |

| 7" | Φ148 | 2155 | Φ50 | 750 | 900 |

| 7 5/8" | Φ160 | 2060 | Φ50 | 750 | 900 |

| 7 7/8" | Φ170 | 2185 | Φ50 | 750 | 900 |

| 10 3/4" | Φ232 | 3855 | Φ70 | 750 | 1050 |

1. This tool can be used alone, also can be combined with drilling, completion and other tools to become a new more functional tool.

2. In the multi joint operation, this tool should be used in conjunction with the sliding sleeve switch and the stabilizer, so as to ensure its normal operation.

Technical Parameters:

| technical parameters | |

| Applicable casing specifications | 5" ~ 10 3/4 |

| Connect thread |

2 3/8"IF•BXP、2 7/8"IF•BXP 3 1/2"IF•BXP、4 1/2"IF•BXP |

Sliding Sleeve Switch

A sliding sleeve switch is a tool that provide differential pressure for the hydraulic packer and other tools that need to be operated by hydraulic pressure in the process of repairing well, well completion and other operations. It works by pitching the ball to the tube.

| technical parameters | |

| Applicable casing specifications | 5" ~ 10 3/4 |

| Connect thread |

2 3/8"IF•BXP、2 7/8"IF•BXP、 3 1/2"IF•BXP、4 1/2"IF•BXP |

Other Types of Kingwell Casing Scraper

| Sharp-Razor™ Series Non Rotating Casing Scraper DIMENSIONAL DATA | ||||||

| Nominal OD(in) | Weight (ppf) | Connection | Centralizer OD(mm) |

Scraper Cage OD (mm) |

ID(in) | Length (in) |

| 4-1/2” | 11.6-15.1 PPF | 2-3/8 REG B*P | 96 3.78’’) | 4.05’’ | 20 | 65 |

| 5” | 11-24.1 PPF | 2-3/8 REG B*P | 9.94’’ | 4.56’’ | 20 | 65 |

| 5-1/2” | 14-43.1 PPF | 2-3/8 REG B*P | 4.33’’ | 5.03’’ | 1 | 69 |

| 6-5/8” | 20-32ppf | 3-1/2 REG B*P | 5.31’’ | 5.86 | 1 | 70 |

| 7” | 26-35 lb/ft | 3-1/2 REG B*P | 5.83’’ | 6.3’’ | 1.18’’ | 74 |

| 9-5/8” | 43-53.5 lb/ft | NC50 B*P | 8.07’’ | 8.77’’ | 2.81’’ | 86 |

| 10-3/4” | 32.75--85.3 | 6-5/8 REG B*P | 9.17’’ | 9.76’’ | 2.81’’ | 98 |

| 13-3/8” | 48-54.5-61-68-72 | 6-5/8 REG B*P | 12.32’’ | 12.83’’ | 2.81’’ | 110 |

5 , 7 , 95/8 .

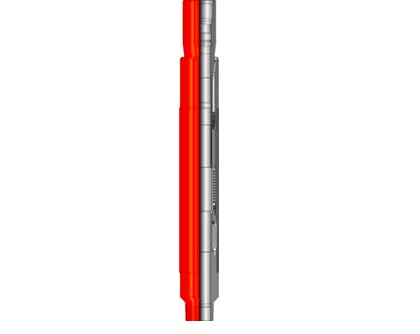

HCS type heavy casing scraper

Introduction

HCS type heavy casing scraper is an effective tool for scraping the inner wall of the casing. The tool is simple in structure and flexible in operation.

Before and after the perforation of new wells, the cement, iron, artillery shells, burr, paraffin, oil and other debris inside casing need to be removed to protect the formation from being polluted. At the same time, to ensure completion tools successfully trip in and achieve sitting requirements of packer and other seal tools. In addition, the well after long-term use, casing inside wall can cause damages, such as reducing, rupture, burrs and other issues. Need to down the through well device to check whether inner diameter is changing, also need to be down the scraper to remove the metal burrs, scale and other material on the inside of casing.

Basic Structure

HCStype heavy casing scraper device mainly consists of: upper joint, the righting sleeve, a centralizer body and scraper frame inner sleeve, scraper frame, right-handed scraper, disc spring seat, disc spring, left-handed scraper, positioning spacer ring, lower joints, seals and other components.

Working Principle

HCS type heavy casing scraper is mainly between the joints and the lower joints fitted with the righting sleeve, a centralizer body and scraper frame inner sleeve, scraper frame, right-handed scraper, disc spring seat, disc spring, left-handed scraper and positioning spacer ring. Right-handed scraper and left-handed scraper is located above the disc spring seat and disc spring. When the GGQX type heavy casing scraper into casing, the blade is pressed to disc spring, disc spring stick to casing wall, pull the tools up and down to scrape the inner of casing.

| Sharp-Razor™ Series Non Rotating Casing Scraper DIMENSIONAL DATA | ||||||

| Nominal OD(in) | Weight (ppf) | Connection | Centralizer OD(mm) |

Scraper Cage OD (mm) |

ID(in) | Length (in) |

| 4-1/2” | 11.6-15.1 PPF | 2-3/8 REG B*P | 96 3.78’’) | 4.05’’ | 20 | 65 |

| 5” | 11-24.1 PPF | 2-3/8 REG B*P | 9.94’’ | 4.56’’ | 20 | 65 |

| 5-1/2” | 14-43.1 PPF | 2-3/8 REG B*P | 4.33’’ | 5.03’’ | 1 | 69 |

| 6-5/8” | 20-32ppf | 3-1/2 REG B*P | 5.31’’ | 5.86 | 1 | 70 |

| 7” | 26-35 lb/ft | 3-1/2 REG B*P | 5.83’’ | 6.3’’ | 1.18’’ | 74 |

| 9-5/8” | 43-53.5 lb/ft | NC50 B*P | 8.07’’ | 8.77’’ | 2.81’’ | 86 |

| 10-3/4” | 32.75--85.3 | 6-5/8 REG B*P | 9.17’’ | 9.76’’ | 2.81’’ | 98 |

| 13-3/8” | 48-54.5-61-68-72 | 6-5/8 REG B*P | 12.32’’ | 12.83’’ | 2.81’’ | 110 |

| Number |

Total length (mm) |

nozzle (mm) |

Casing PPF |

Centralizer OD mm |

Blade OD max. (mm) |

Body OD (mm) |

Connection (API) |

Max. Tensile (t) |

Max. torque (KN.M) |

| HCSX50 | 1738 | 25.4 | 11.5-15 | 103 | 118 | 103 | 2 3/8REG | 65 | 25 |

| HCSX54 | 1738 | 38 | 14-17 | 103 | 118 | 103 | NC31 | 80 | 30 |

| HCSX70 | 1800 | 47 | 17-29 | 148 | 168 | 148 | NC38 | 120 | 40 |

| HCSX95 | 1800 | 70 | 36-58.4 | 210 | 230 | 210 | NC50 | 150 | 50 |

casing scraper is a durable

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve